Planning

and production

of braking system fittings

for railway vehicles

Production

Production is carried out according to our catalogue and based on the client’s requirements through CAD 3D software planning. All new products are prototyped and monitored all through production and then tested.

Details are obtained from bar and mould using hi-tech machines. On client’s request, various thermal treatments are available internally while the galvanic treatments are carried out externally.

Train Braking System Fittings

The manufacturing principle of SIRIT fittings ensures optimal tightness also between pipes not perfectly aligned (allowed axial deviation ±4°) or exceeding normal tolerances of both effective external diameter, roughness and possible ovalizations. In addition, they are suitable for thermal conditions ranging from -30° C to + 110°C and under vibration stress. They are compatible with copper, steel, stainless steel, aluminium and nylon pipes. Our fittings are made with brass and galvanized to increase resistance to corrosion and may be used in the following sectors: building, naval, industrial, railway, industrial vehicles.

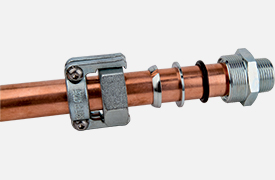

RTAU® One-Way Security Collar

In order to achieve greater and prolonged safety in time, we designed the “RTAU® Safety Collar” which revolutionary design locks the nut inside SIRIT’s and other manufacturers’ fittings and prevents the pipe from unscrewing and unthreading. This device may also be used on already installed and working systems.