production

PIPE FITTINGS PLANNING AND DESIGN FOR THE RAILWAY SECTOR

This new kind of manufacturing applies to the following sectors:

- Railway

- Industrial

- Naval

- Civil

- Agricultural

- Oil-pressure plants

The o-ring seal with cut conical ring on which the new product range is based has been designed, prototyped and monitored during manufacturing and subsequently tested by AQM and TUV.

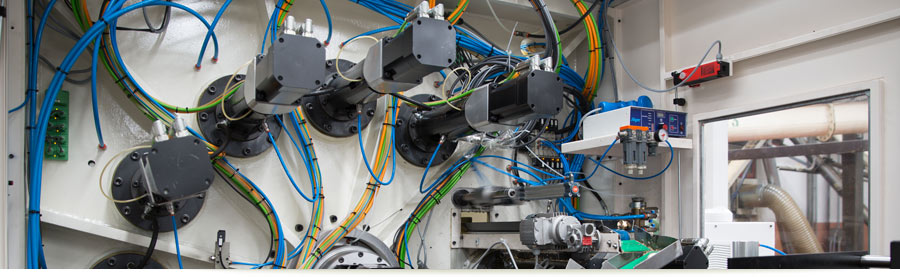

PRODUCTION AND QUALITY CONTROL

Pieces are obtained through bar processing and molding with high-tech machines operated by specialized staff which results in high manufacturing capacity supported by an efficient and systematic quality control through SPC in compliance with UNI EN ISO 9001:2008.

WASHING

Pieces are vacuum washed with zero-emissions solvents or washed automatically in water at the end of the production cycle.

THERMAL AND SURFACE TREATMENTS

Fe/Zn 8-UNI ISO 2081 white passivation with trivalent chrome (hexavalent chrome-free) with sealing (in compliance with the European Directive 2000/53/Ce). All pieces are internally normalized to eliminate processing solicitations on the material. Various external galvanic treatments are available on request.